Finding a Custom Solution

At RK Rubber, we excel at developing super-sized rubber solutions for mission critical projects. Many natural rubber fabricators in our industry do not have the capacity, equipment, or experience to work with large, heavy rubber stock.

For over 125 years, we’ve built our reputation by solving problems with innovative, customized solutions that have to perform without failure. A long-time customer in the construction industry already knew that our gaskets had a reputation for 5-year life spans in tough conditions, so they brought us on board to help solve their issue.

Unique Precision Parts

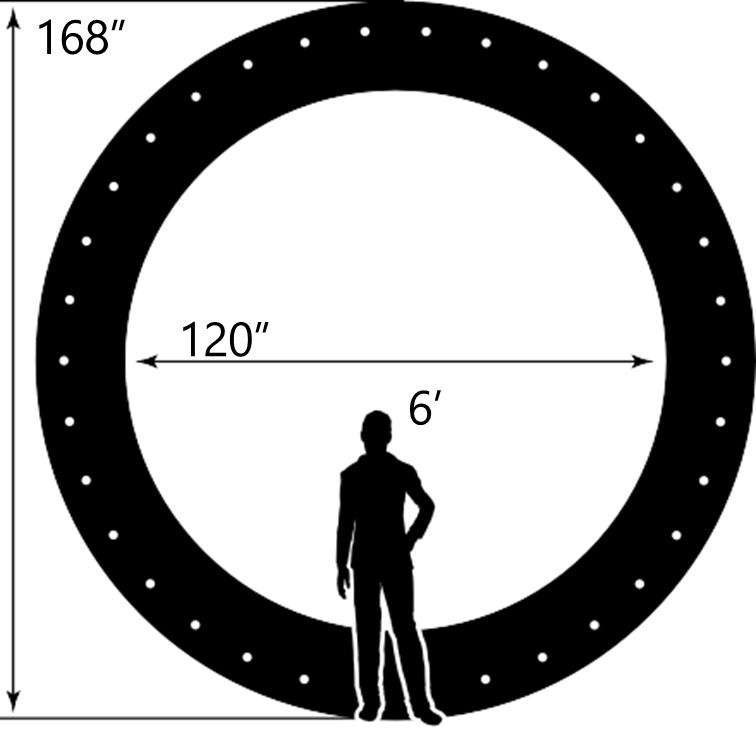

They asked us to design and fabricate a super-sized rubber gasket with a 14’ OD and a 10’ ID. Gaskets of this magnitude cannot be made in one piece due to eventual splicing failure. In addition to its massive size, the physical properties had to perform in extreme conditions where extensive high-pressure water, mud, rock and debris flowed past it. The construction teams would ultimately use the gasket for a wide range of deep tunnel boring machines during big dig projects.

We understood that any type of gasket failure could result in massive construction delays and wasted municipal dollars. This was a one-off job and it required thorough design and exceptional craftsmanship. Using diligent engineering and intricate fabrications techniques, our team successfully created a 168” OD gasket with six rubber segments that were each made from 1” thick neoprene stock.

Engineered Rubber Solutions

We leveraged an array of fabrication and vulcanization processes to meet our customer’s requirements. In addition, we performed all of our work under a tight deadline of less than two weeks. We also assisted them with developing a suitable transportation plan that ensured the gasket would arrive on-site as quickly as possible. The project was a resounding success, and we continue to assist them with large-scale gasket manufacturing for various municipal construction projects.