Conveyor Belts

We fabricate rubber conveyor belts in our own production facility using state-of-the-art equipment. Our experienced team receives continuous education and training through NIBA (The Belting Association) to learn the latest advancements in splicing and fabrication. We have the capabilities to fabricate and install conveyor belting.

In-House Capabilities

- Cleated Magnetic Separator Belts

- Perforations for Drainage or Vacuum Application

- Hot Vulcanizing for Cleats and Vanner Edges

- Corrugated Sidewall

- V-Guides in Various Profiles

- Impressions Coverings

- Machining of Grooving and Profiles into Covers

- Fabrication of Endless Belts

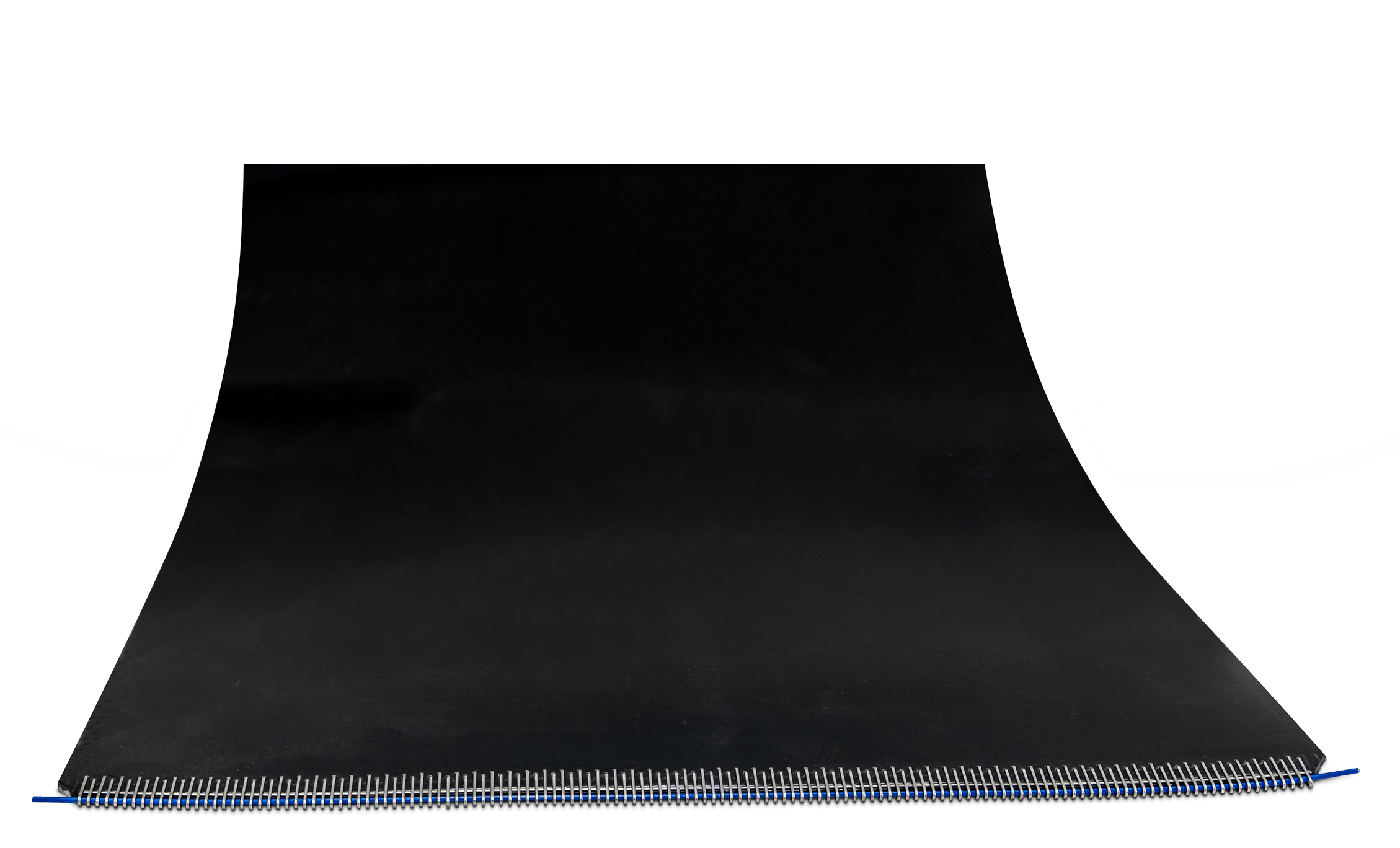

- Fabrication of Open End or Prepared Laps

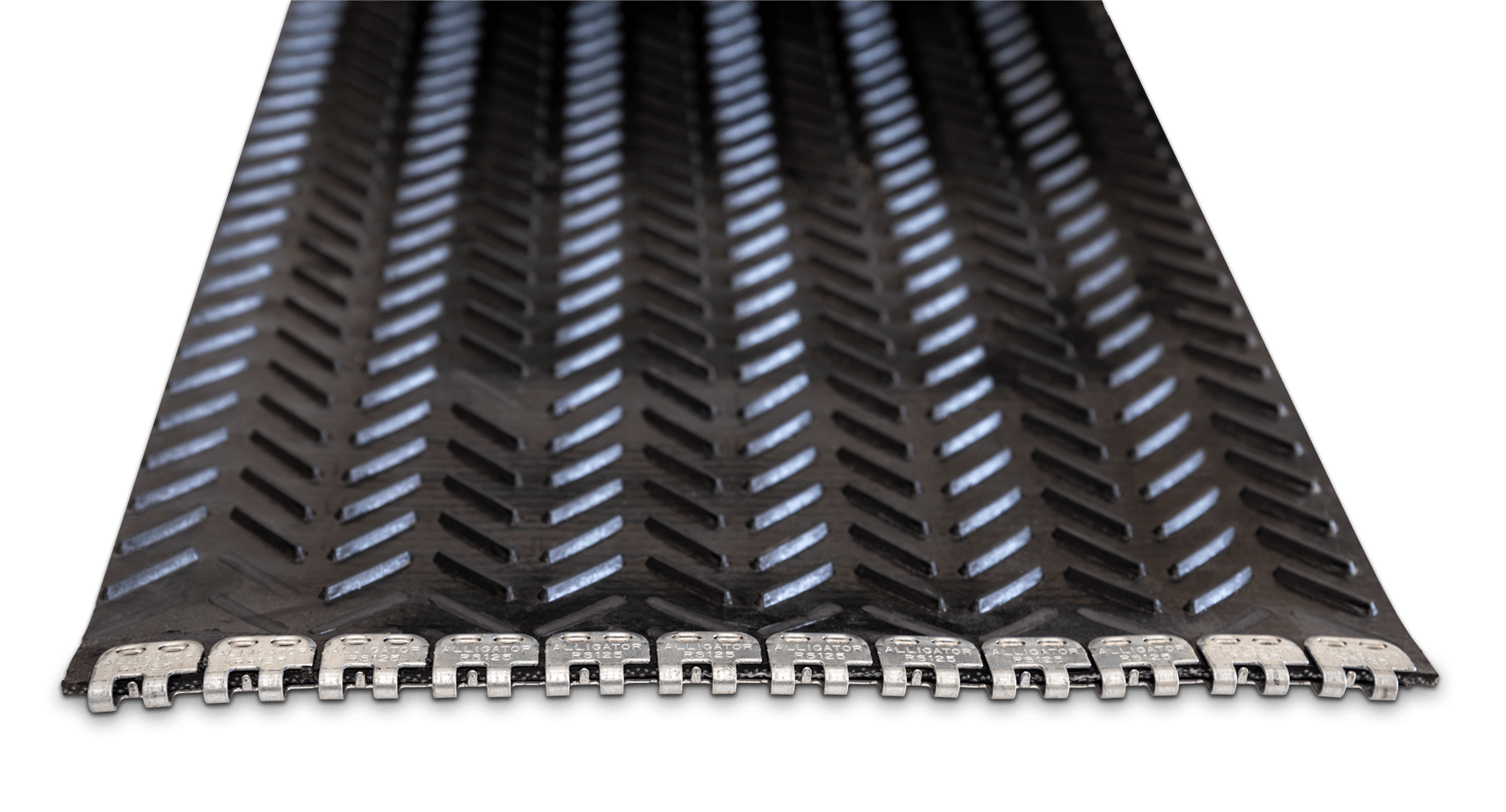

- Installation of Mechanical Fasteners (Flexco & Super Screw)

Conveyor Belt Options

- Heavy Duty Black Rubber Belting

- Molded Cleat for Incline

- One Off Reproductions

- OEM Replacement

- Solid Woven/PVC

- Non-Marking Compounds

- Sponge and Rubber Covering for Flat or Power Belts

- Compounds for Grab or Release

- High or Low Operating Temperatures

- Food-Grade Material Requirements

- Lightweight/Monofilaments