Materials

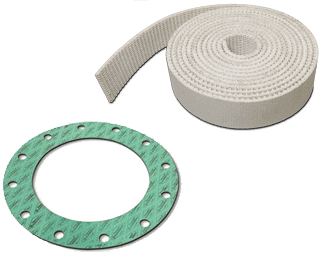

RK Rubber Integrity

At RK Rubber, we provide only the best rubber compounds sourced from within the U.S. We consult with our customers to understand application use and make the best recommendations based on our expertise.

As a leading fabricator, RK Rubber offers a complete range of synthetic rubber materials suited for a variety of applications.

Not all rubber materials are created equal

We strive to provide materials that meet ASTM specifications. In today’s global marketplace, many suppliers falsely position materials that are “designed” to meet specifications. Some products such as commercial-grade neoprene may actually contain little to no neoprene. If material cost is very low, be aware that you are most likely not getting what you really want or need. Watch out for “commodity” grade materials with low-quality physical properties.

Many times we are asked to make material or product recommendations for specific applications. We are happy to make suggestions based on our years of experience in the rubber and belting industry and the application details given to us by customers. Each application can have unique challenges and varying degrees of specific and accurate details relating to use, therefore a material or product recommendation may offer varying degrees of success or longevity in your unique application.

To select the correct rubber material for your project, important considerations should be made about application factors including:

- dynamic or static application

- system pressure

- chemical compatibility

- heat, cold and friction

- material cost

- design factors

- installation practices

- use of the product

- projected life of product

- maintenance frequency

RK Rubber experts help determine the best rubber materials to use and provide prototypes for application-specific testing to ensure top performance.

We develop the best solution for you from a wide variety of non-metallic rubber materials, plastics, rubber compounds, silicone rubber, and rubber sponge materials.

RUBBER COMPOUNDS

Butyl

Butyl can be used as a general use rubber as it has good chemical resistance. Since butyl has a much higher permeability to air than most rubber products, its uses are vast. Among its wide variety of uses are tire tubes.

Cloth Inserted (CI) (or Diaphragm)

CI rubber is reinforced with cloth making the material able to withstand stronger compression applications. It also has a good resistance to alkalis and acids. Appropriate uses for the material include hot water, low pressure steam, and hydraulic systems.

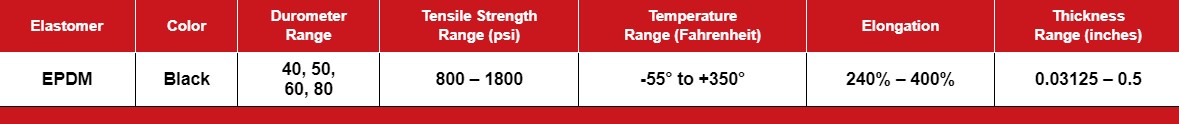

EPDM

EPDM rubber is generally used in applications that require outstanding weather, ozone, or temperature resistance. EPDM also has a great resistance to animal and vegetable oils, and excellent resistance to acids, alkalis, and ketones. EPDM is NOT compatible with petroleum based oils.

Hypalon

Hypalon, a synthetic rubber, has a good resistance to heat, oil, and chemicals. It can also have good resistance to weather, abrasions, and fires. Another property of hypalon is its ability to maintain its color during use. Many hypalon uses include hosing, power steering hoses, and fuel hose covers.

Neoprene

Neoprene rubber is a general purpose compound that offers oil resistance and has good chemical stability. It is also able to remain flexible over a wide temperature range. Generally, the many different grades of neoprene have a direct correlation to the actual percentage of neoprene in the compounds.

Nitrile Buna – N

Buna – N has excellent resistance to petroleum-based oils. It also has good resistance to heat, abrasions, water, and gasoline. Nitrile Buna – N can be used for automotive applications.

Pure Gum

Natural rubber has excellent physical properties. A true floating stock will have very good tear strength and abrasion resistance. It is also non-marking and non-toxic, and made with FDA ingredients.

PVC Sheet (Vinyl)

PVC sheet, or vinyl, has very good resistance to oils and low permeability to gasses. While its resistance to UVs is good, it has excellent resistance to acids, bases, alcohols, and mineral oils. Although it has low resistance to hot and cold temperatures, PVC sheet has excellent aging characteristics.

Silicone

Silicone rubber is a semi-organic synthetic compound. It contains a chain of silicon and oxygen atoms, rather than carbon and hydrogen found in other rubber products. This results in a very flexible structure with a wide range of high-performance physical, mechanical and chemical properties. Silicone’s chemical structure creates a fusion of the qualities of metals, with the diversity of plastic.

Skirtboard Rubber (SBR)

SBR has good tear and abrasion resistance. It is most commonly used to protect conveyor frames, chutes, and various other high impact areas.

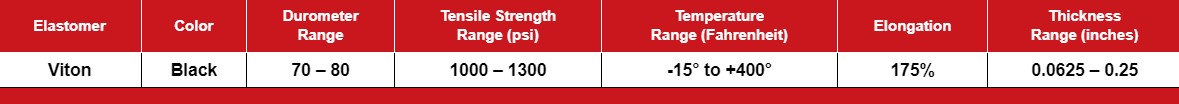

Viton

Viton is a high grade compound that has excellent resistance to high heat, chemicals, and weather, making this product a great choice for use in highly corrosive environments. Viton offers superior mechanical properties and compression abilities. Applications include fuel systems seals, chemical-resistant gasket seals and rubber o-rings.

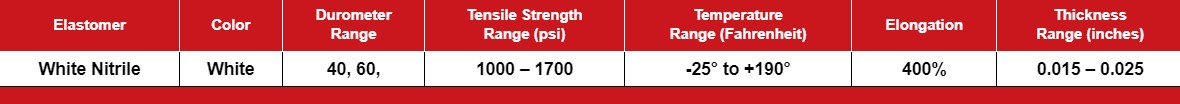

White Nitrile

White nitrile is manufactured from FDA-approved ingredient, such as food, pharmaceutical, and cosmetic processing. White nitrile offers good abrasion resistance and handles oily and greasy products well.

SPONGE RUBBER MATERIALS

Sponge Rubber – Open Cell

Open cell sponge rubber is calendered and injected with gas to make it cellular. Most open cell is natural rubber and is a great cushioning material that can compress and recover quickly. It has low pressure sealing against gases and is weather resistant.

Open cell sponge rubber can be made of silicone or other polymers such as neoprene, EPDM, nitrile, etc. and is manufactured in rolls. Exact open cell sponge rubber properties depend upon the type of polymer used.

Properties of Open Cell Sponge Rubber

- Flexibility Retained in Low Temps

- Resilient

- Resistance to Acids & Bases, Light Oil Contact, Ozone, Oxidation, Moisture, Some Sunlight

- Excellent Compressibility with Good Rebound

Typical Applications for Open Cell Sponge Rubber

- Die-cut Parts

- Rubber Gaskets and Seals

- Insulating and Weather-stripping

- Shock Absorption, Cushioning

- Sound-Proofing

- Vibration Dampening

- Thermal Insulation

- Filtering

Sponge Rubber – Closed Cell

(Expanded Sponge Rubber)

Closed cell sponge is made in buns (gas expanded) and cut to thickness. Most closed cell sponge is neoprene or neoprene blend and is an ideal medium for protection in uses to prevent water or air from passing from one area to another at low pressures. It has high flexibility and compression capabilities and can conform to and seal most surfaces.

Closed cell sponge rubber can be made of silicone or other polymers such as neoprene, EPDM, nitrile, etc. and is made in relatively small 42 inch x 72 inch sheets. Exact properties depend upon the type of polymer used. The closed cells are expanded with nitrogen gas which is generated during forming and/or curing.

Properties of Closed Cell Sponge Rubber

- Flexibility Retained in Low Temps

- Resilient

- Resistance to – Acids & Bases, Light Oil Contact, Ozone, Oxidation, Moisture, Some Sunlight

- Excellent compressibility with variable compression set characteristics

Typical Applications for Closed Cell Sponge Rubber

- Die-cut Parts

- Rubber Gaskets and Seals

- Insulating and Weather-stripping

- Shock Absorption, Cushioning

- Sound-Proofing

- Vibration Dampening

- Thermal Insulation

- Filtering

NON-METALLIC MATERIALS

Non-metals are organic substances that do not conduct heat or electricity, and are structurally brittle (cannot be easily rolled, molded, extruded or pressed). Chemically, the non-metallic elements in the periodic table are hydrogen, carbon, nitrogen, oxygen, phosphorus, sulfur, and selenium. The world of industrial non-metals incorporates substances made from combinations of these elements. RK Rubber works with non-metallic substances that include:

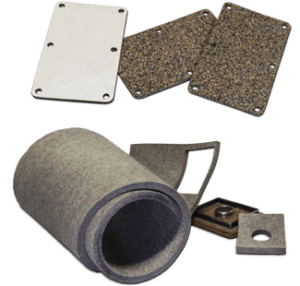

Cork and Rubber

Plant-derived substance based on an arrangement of cellulose, combined with a polymer and/or vegetable fibers.

Properties of Cork and Rubber:

- Easy to Cut

- Light Weight

Typical Application for Cork & Rubber:

- Flanges

Felt Products

Organic wool fibers, can be combined with polymers.

Properties of Felt Products:

- Absorbs Oil; Performance is not compromised by Oil Saturation

- Durometer – Hard or Soft

- Insulating

- Resilient, Cushioning

- Resistant to Compression, Fraying, Wear

Typical Applications for Felt:

- Bearings & Spacers

- Gaskets, Rings, Seals, Washers

Non-Asbestos

A composite material of compressed ceramic and/or organic fibers, developed as a safer alternative to asbestos.

Properties of Non-Asbestos Rubber Products:

- Easy to Cut

- Flexible

- Insulating

- Fire Safe

- Thermally Stable

- Resistant to Mild Acids & Bases, High Heat, Inert Gases, Oils, Pressure, Steam, Water

Typical Applications for Non-Asbestos Material:

- Brake Pads

- Clutch Facings

- Gaskets

Vegetable Fibers

Plant-derived substance based on an arrangement of cellulose; can be spun into filaments or matted into sheets. Can be combined with cork and/or a polymer.

Properties of Vegetable Fiber Rubber Products:

- Easy to Cut

- Low Cost

- Insulating

- Low Temperature Performance

Typical Application for Vegetable Fiber Materials

- Gaskets for Low-Pressure Usage

- Insulating gaskets

- Refrigeration gaskets

PLASTIC MATERIALS

Plastic materials are high molecular weight compounds comprised of two or more repeating organic or synthetic base molecules.

Special consideration is given to fabrication of plastics properties including use temperature, coefficient of thermal expansion, thermal conductivity, and tensile strength.

We use a wide variety of high-quality plastic material types and grades to achieve your unique application needs.

Acetate (Cellulose Acetate)

Polymer of wood pulp or cotton fibers

Properties of Acetate

- Clear / Good Optical Properties

- Dimensionally Stable

- Easily Cut or Torn

- Food and Medical Grade

- Printable with conventional methods

Typical Applications for Acetates

- Packaging

- Graphic Arts Designs

- Printed Overlays

- Printing and Display

- Sheeting

Mylar (Polyester Film, Plastic Sheet)

Properties of Mylar

- Clear

- Durable

- Dimensionally Stable

- Non-Yellowing

- Resistant to High Heat and Tearing

Typical Applications for Mylar

- Apparel

- Die-Cutting

- Electronics

- Packaging

- Protective Overlay

- Printing and Display

Urethane (Polyurethane diisocyanate, CU)

Available in liquid cast, urethane sheets, millable gums and thermoplastic form; each with different benefits

Properties of Urethane

- Resistance to –

- Abrasion

- Cuts and Tears

- Fuel

- Oil

- Wear

- Tensile Strength

Typical Applications for Urethane

- Blades and Scrapers

- Bumpers

- Conveyor Belts and Conveyor Belt Covers and Liners

- Electrical Insulation

- Gaskets and Seals

- Injection Molding or Molded Urethane Parts

- Thermoplastic Urethane

- Non-Marking Components

- Rollers

- Sound-proofing

- Tires and Wheels

Styrene (Vinyl Benzene)

Organic liquid used in the manufacture of many polymers, like:

- Polystyrene

- ABS – Acrylonitrile Butadiene Styrene

- SBR – Styrene Butadiene Rubber

UHMW Polyethylene (Ultra-High Molecular Weight Polyethylene)

Properties

- Easy to Machine

- Food-Grade

- Low-Friction

- Non-Stick

- Performs Well from Low to High Temps