Custom Rubber-Based Solutions

At RK Rubber, we work collaboratively with our customers to develop creative, out-of-the-box solutions in order to protect their equipment while operating in extreme environments. This is especially true for the foundry industry, where we designed, tested, and manufactured shroud covers for our customer’s robotic stations operating in blast cabinets.

The extreme heat, sand, and water ejections continuously affected the robots. Each system ranged from $50,000 to $80,000 in cost. The original protective covers consistently failed, causing expensive equipment damage and ongoing maintenance that resulted in significant downtime. While we contacted several other rubber vendors, none of them could offer an effective solution.

Initial Draft and Design

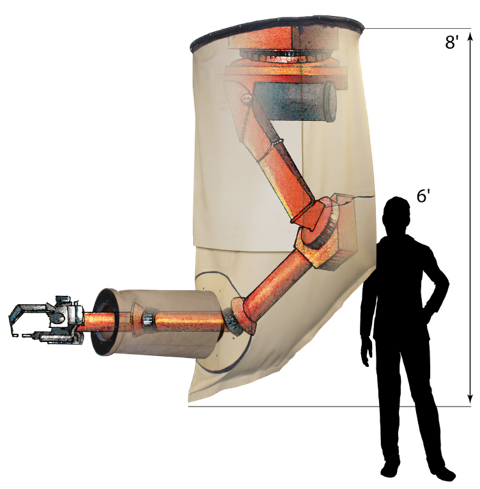

Working directly with staff at their Wisconsin foundry, our initial prototype consisted of a blue tarp and duct tape that helped us test and determine the shroud’s required shape. The team aimed to protect the robots while they hung from the ceiling. Utilizing gravity, the prototype shroud draped underheat the robot as it performs its routine. The space created between the robot and rubber shroud allowed the unit to continue operations unhindered while shielded from the elements.

The initial tests were a resounding success and ultimately helped us determine the shroud’s final shape and position. For the shrouds material, we selected a pure gum rubber with a smooth finish; well-known for its abrasion resistance. Using our longitudinal splicing process, we fabricated shroud covers that featured dimensions of 8′ high and 48” in diameter. Our team produced each shroud in-house using our state-of-the-art lathe, vulcanizer, and grommet installer.

Final Development and Use

From initial concept design and testing to final manufacturing, our team was able to develop a prototype cover within 3 weeks. We prevented, and in most cases eliminated, premature failure that had occurred while each robot performed its duty along the production line.

Our creative thinking impressed our customer, and they quickly expanded the use of our shrouds in each of their foundry locations. They now order up to 40 shrouds per year and we continue to help them develop ways to protect other equipment, maintain production efficiency, and improve their bottom line.